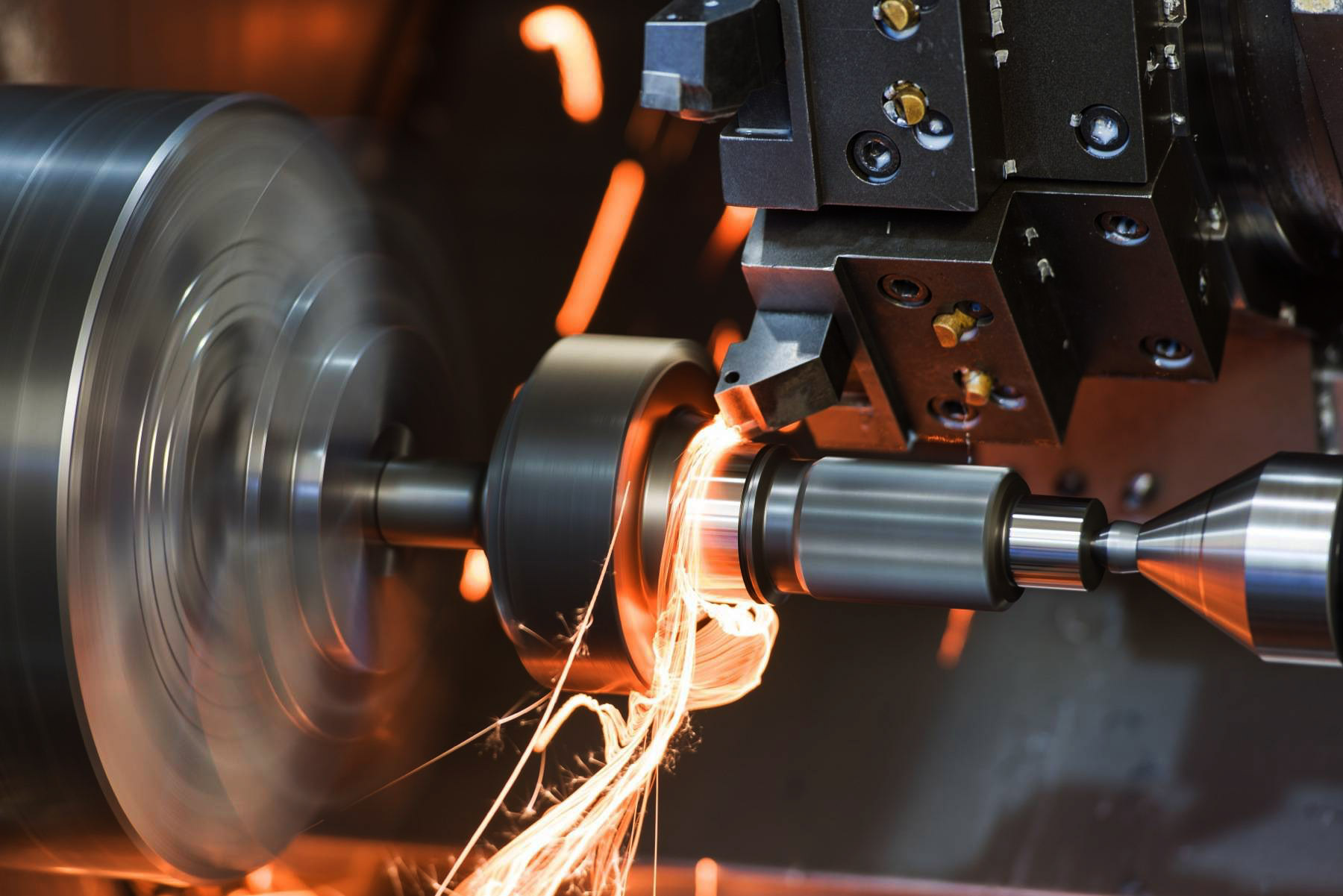

Laser welding technology allows for strong and precise joints on metal surfaces with minimal heat impact. It is especially preferred for mold surface repairs, fine part joining, and the welding of sensitive components.

During welding, no deformation occurs in the part, and the need for additional grinding or processing after the operation is minimized. This provides both time and cost advantages. Moreover, durable solutions are offered with high-strength connections.

Laser marking enables data such as logos, serial numbers, and barcodes to be applied to products without contact, making them resistant to wear and chemicals. This method offers significant advantages in both traceability and aesthetics.

Our company provides high precision, speed, and quality in both welding and marking processes with laser systems. We develop customized solutions to contribute to manufacturing processes.