-

Our Services

- Product Design

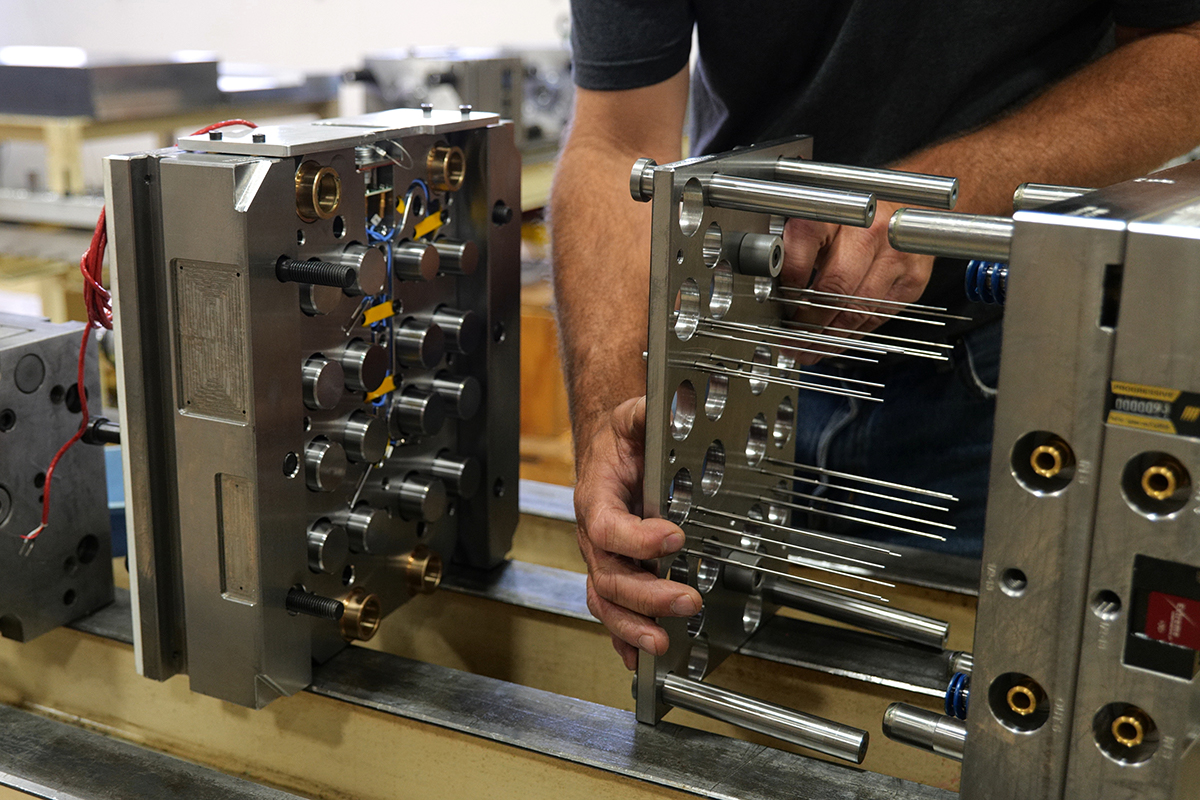

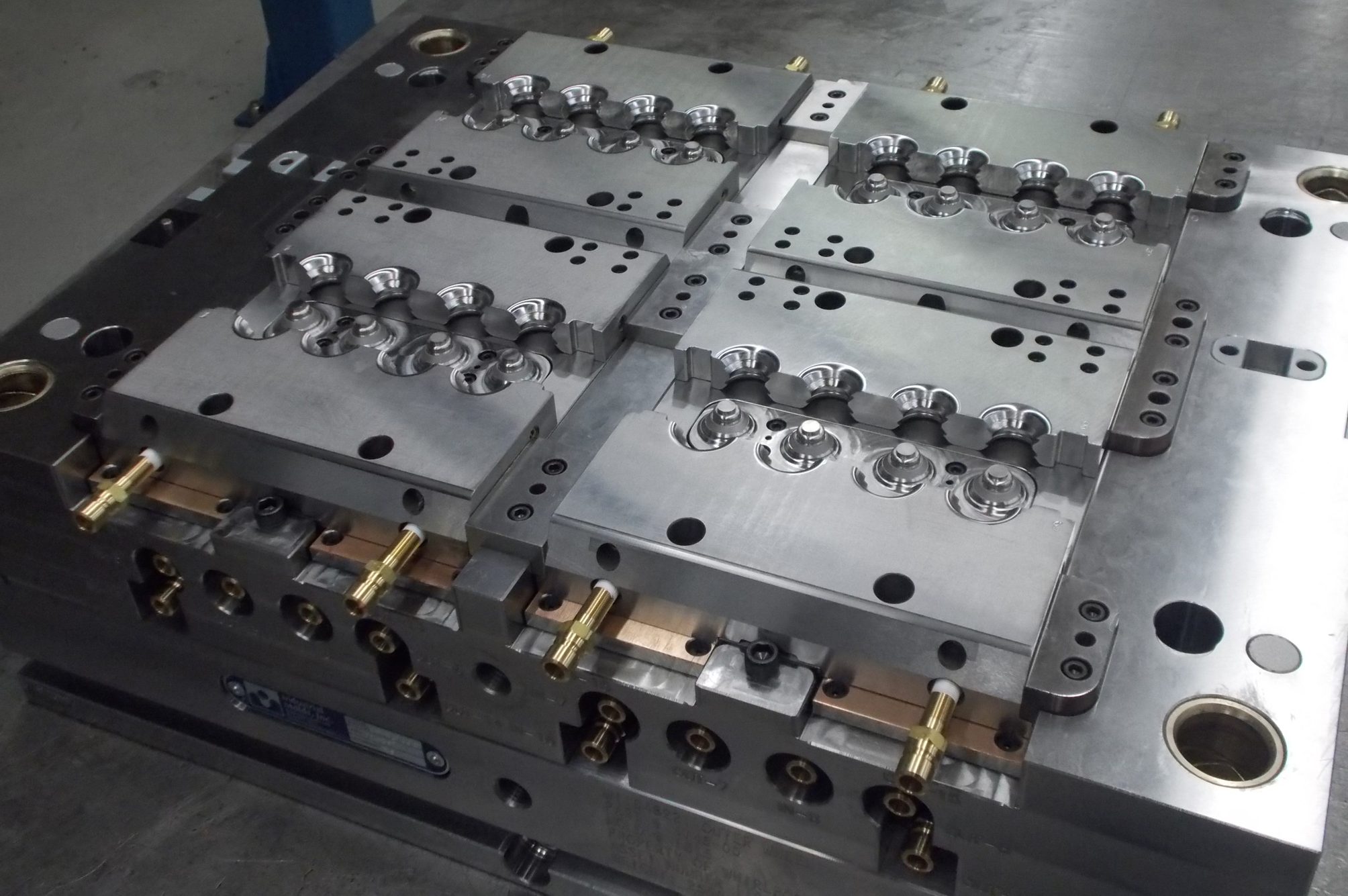

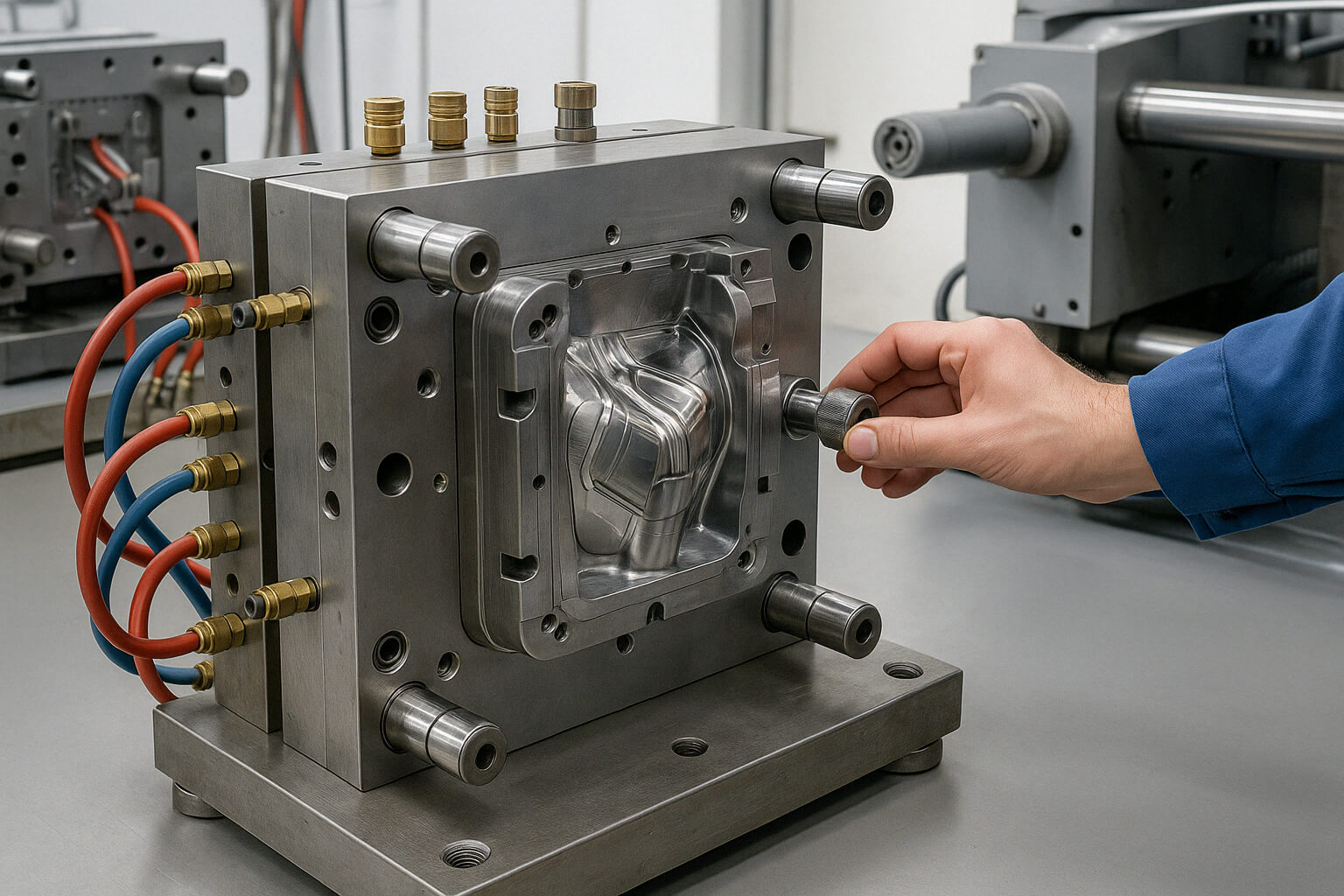

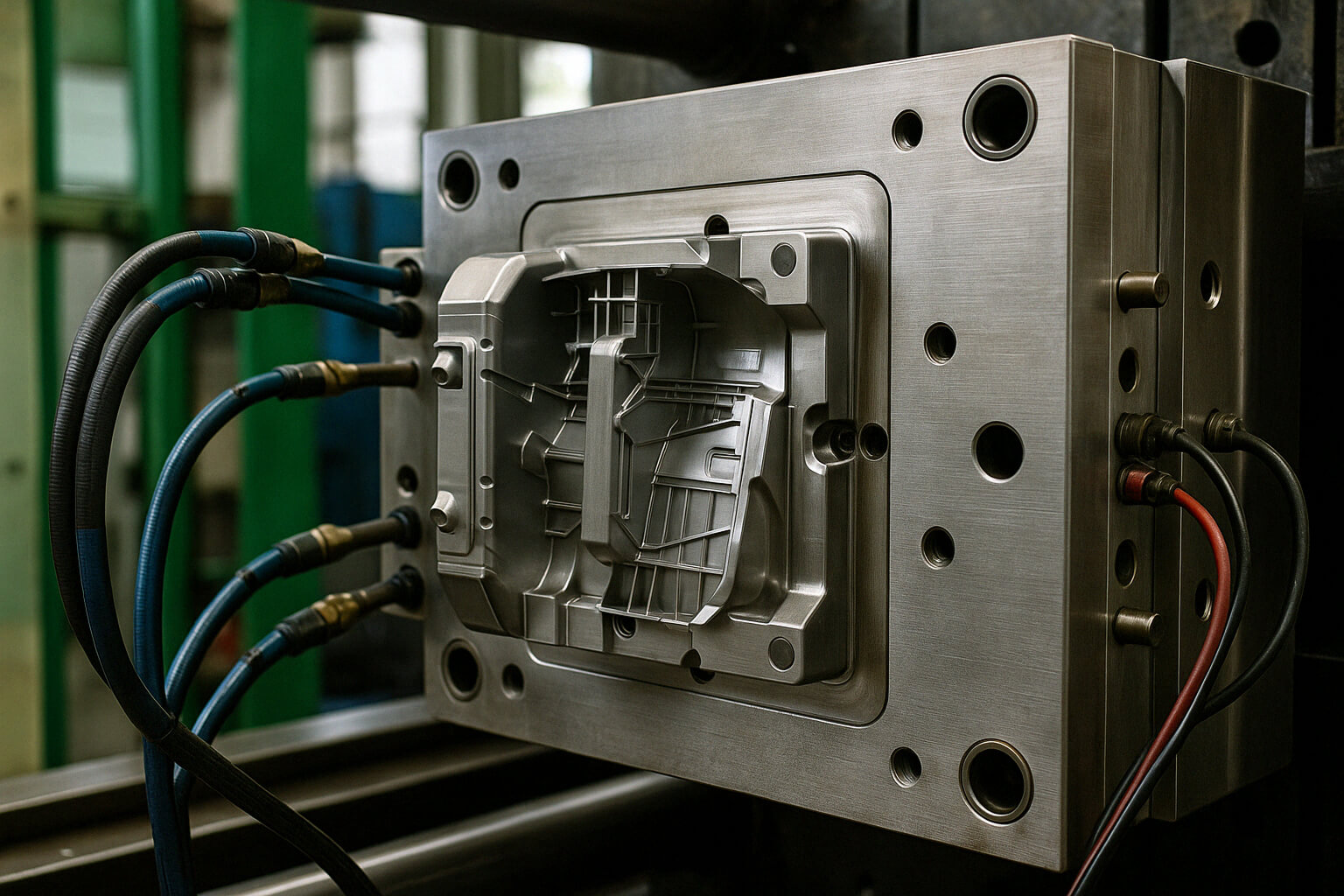

- Mold Design

- Mold Revision, Modification, Improvement

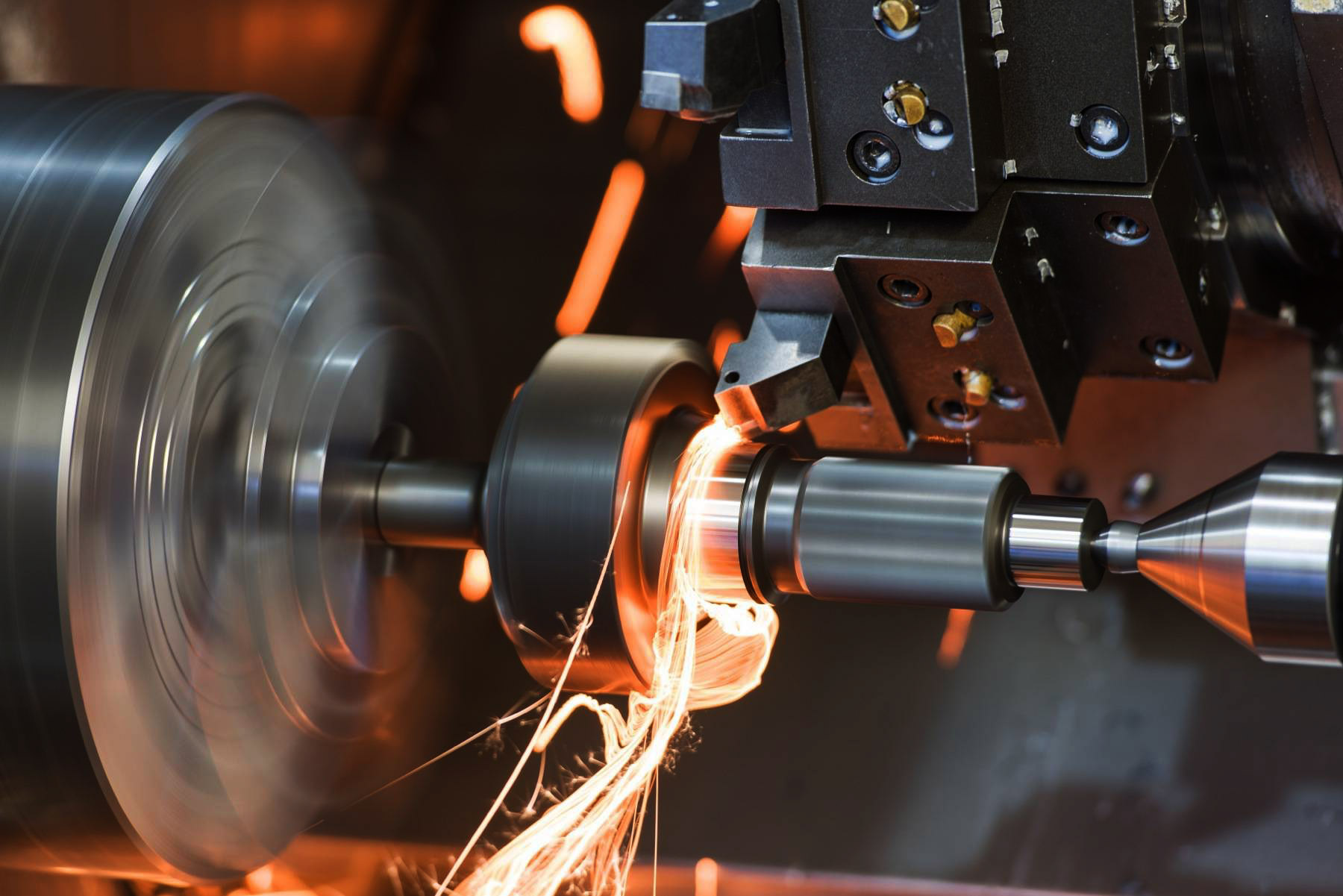

- Chip Manufacturing

- Engineering Services (Design, Product, Process)

- Control Fixture Manufacturing

- Assembly Fixture Manufacturing

- Measurement Services (CMM)

- Laser Welding & Marking

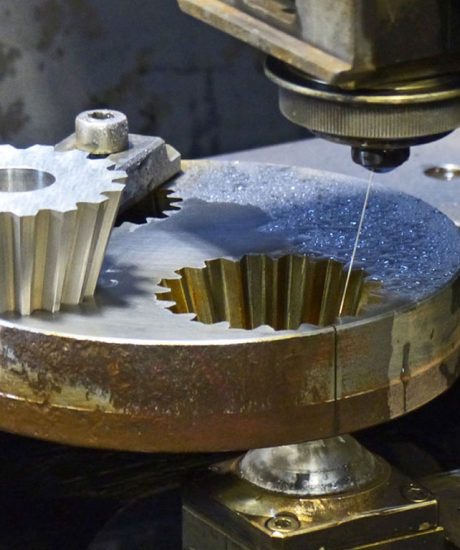

- Wire Erosion Works

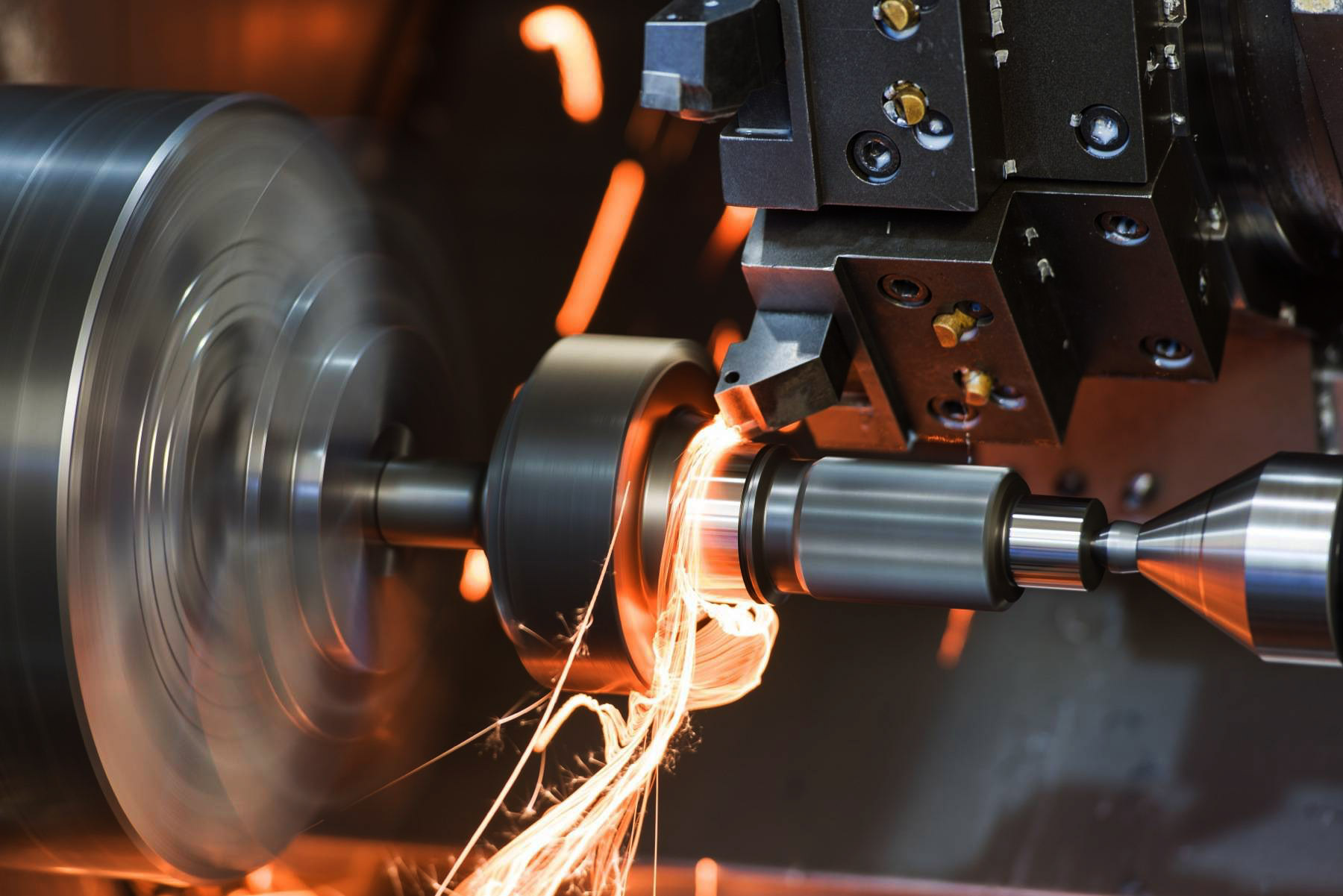

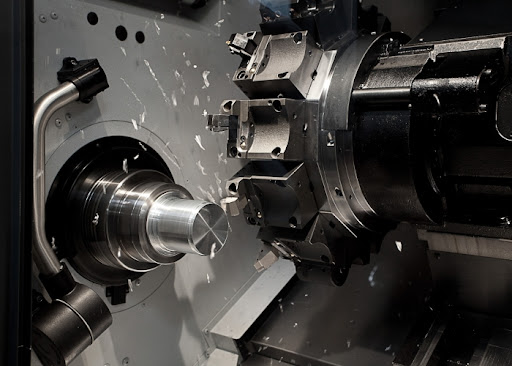

- CNC Machining

- 5-Axis CNC Machining

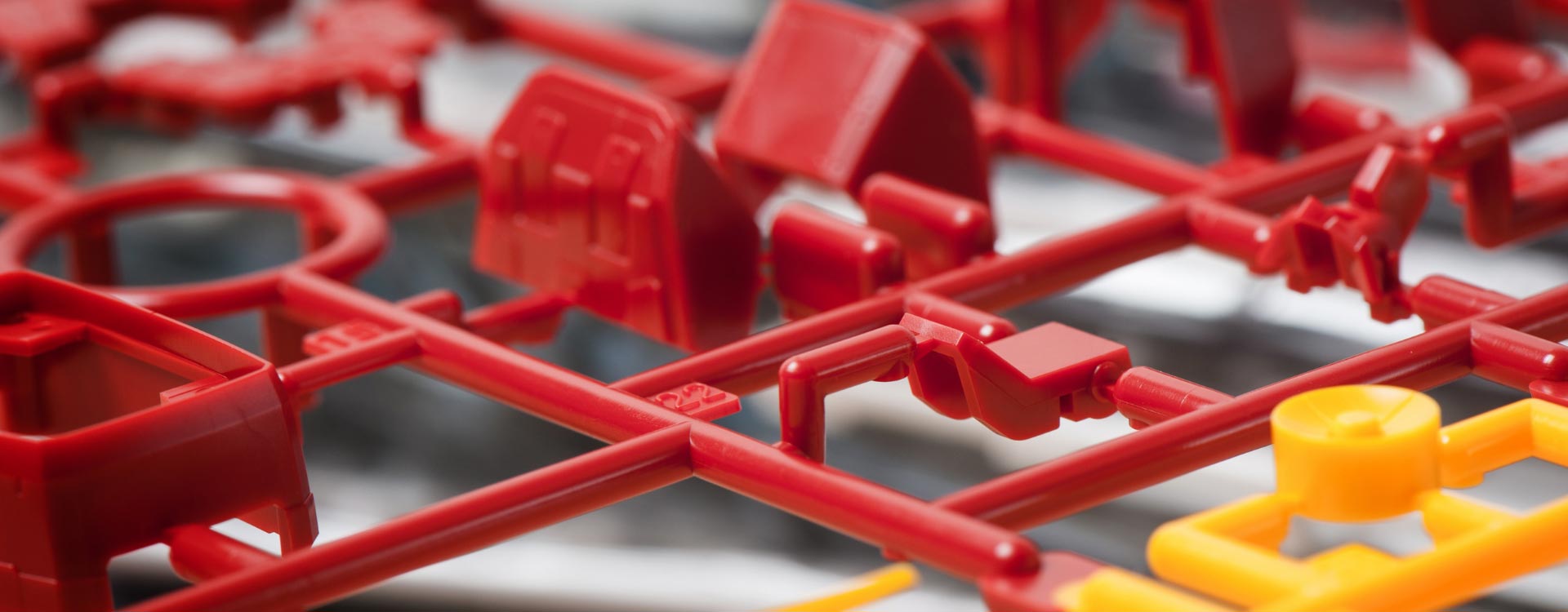

- Plastic Injection Mold Manufacturing and Revision

- Plastic Injection Part Manufacturing

- Our Solutions

- Contact