With over 20 years of experience, our company specializing in mold and fixture manufacturing offers engineering and production solutions to many sectors, primarily automotive. Operating with the principles of quality and technical excellence at every stage of the production process; from design to manufacturing, from revision to plastic part production, we become your solution partner with a wide range of services.

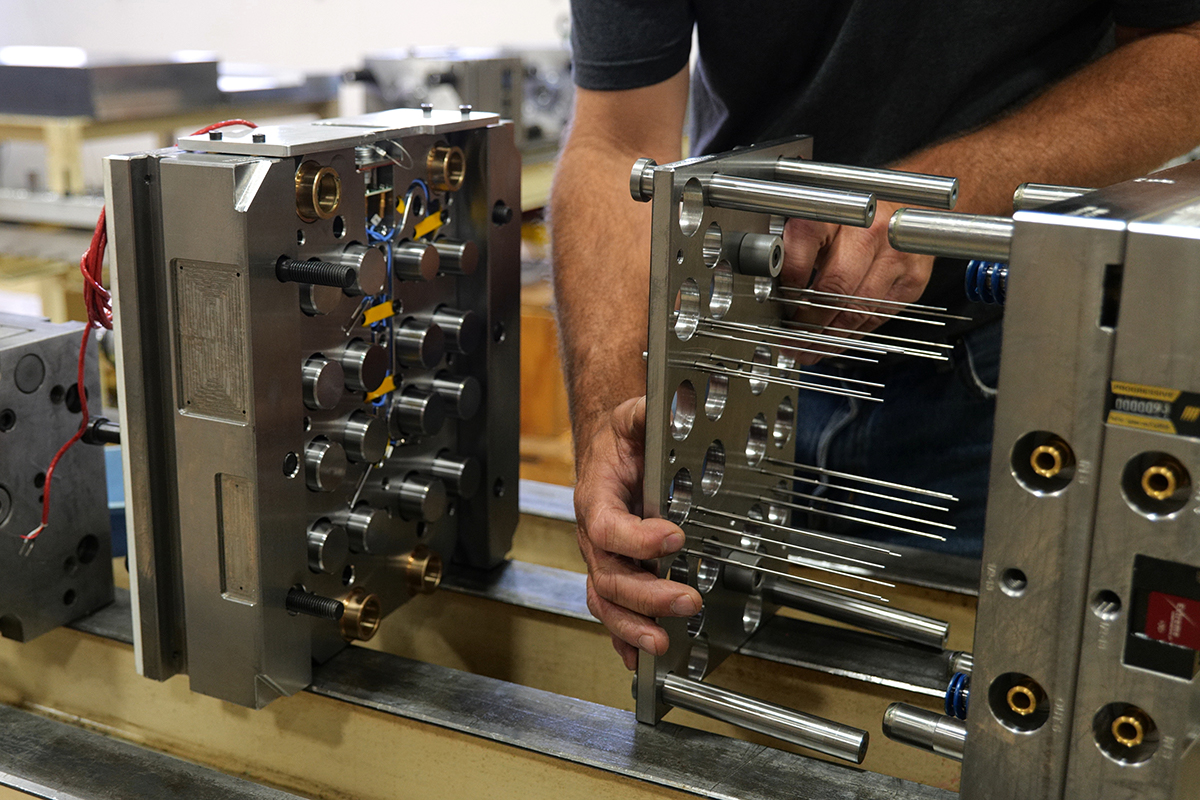

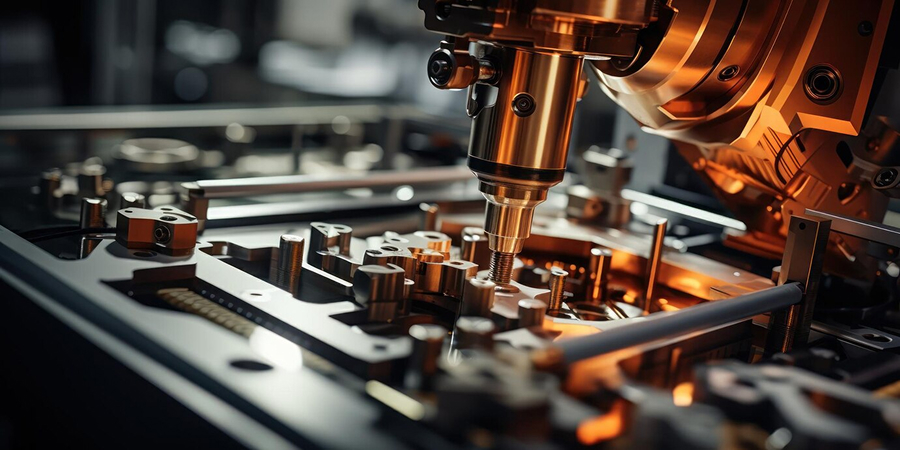

Mold design and CAD/CAM-supported engineering services come into play at the initial stage of the project. Designs developed specifically for the needs are realized through precise manufacturing processes. In addition to plastic and sheet metal molds, assembly fixtures and inspection fixtures, which are indispensable for production lines, are also produced with high-quality standards.

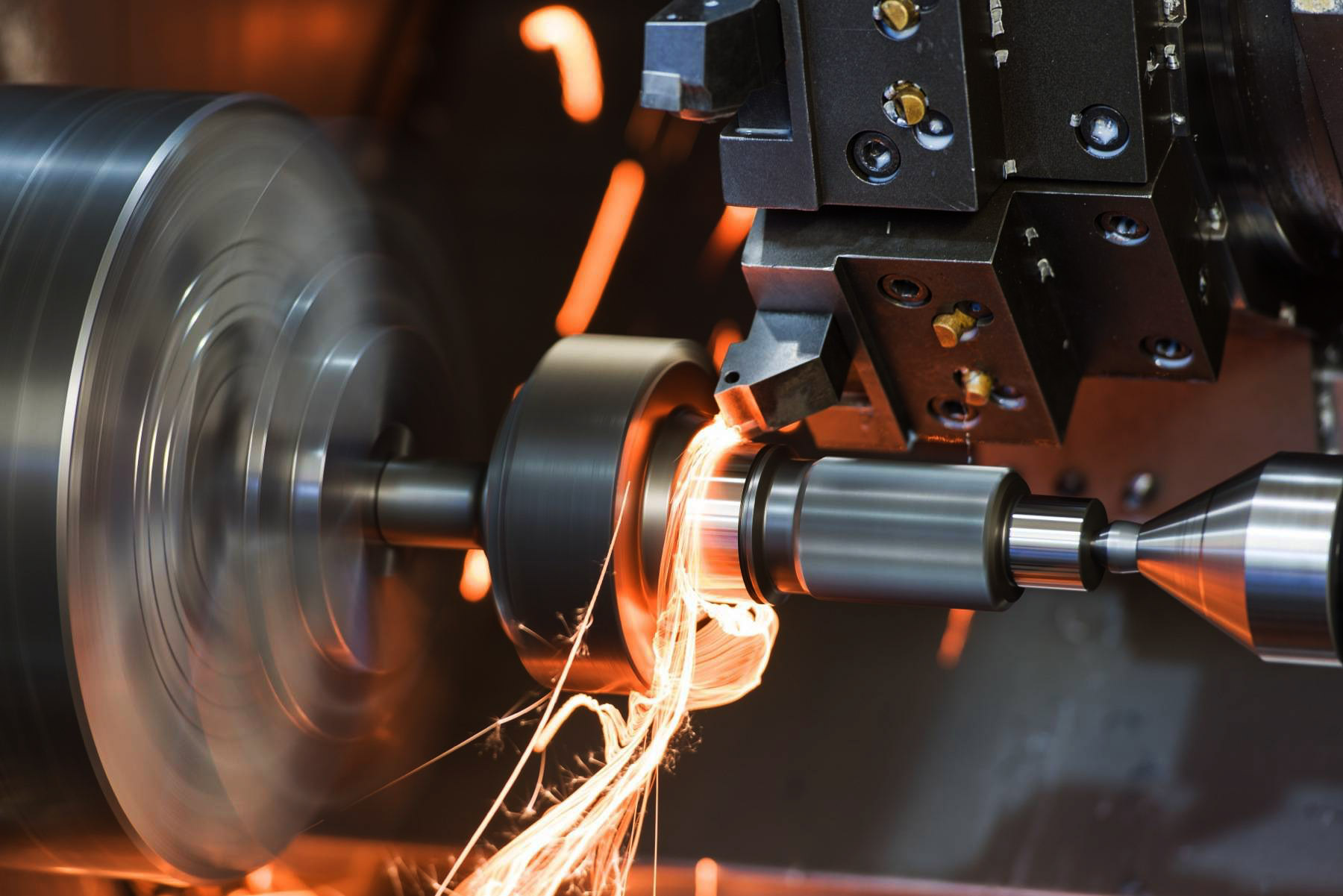

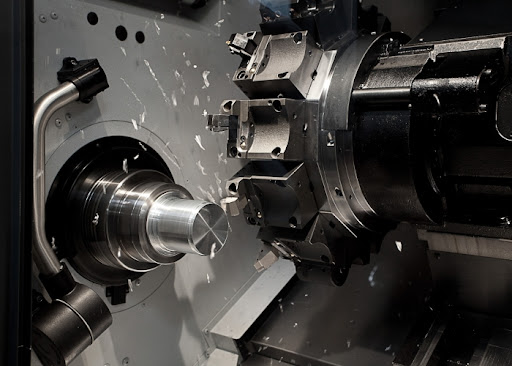

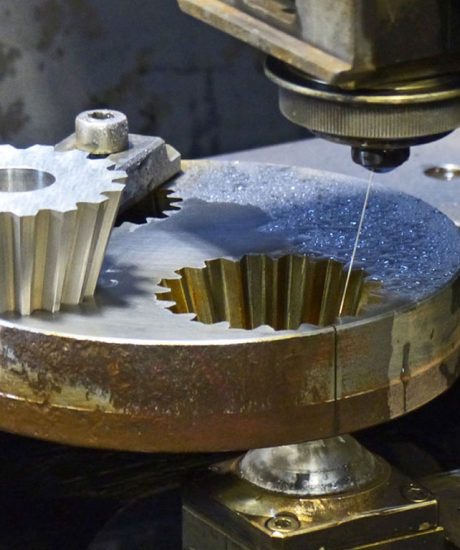

Revisions, modifications, and improvement services offered for existing molds ensure production continuity and extend equipment lifespan. Additionally, in the machining department, various materials are shaped with precise processing techniques, and high-tolerance parts are produced.

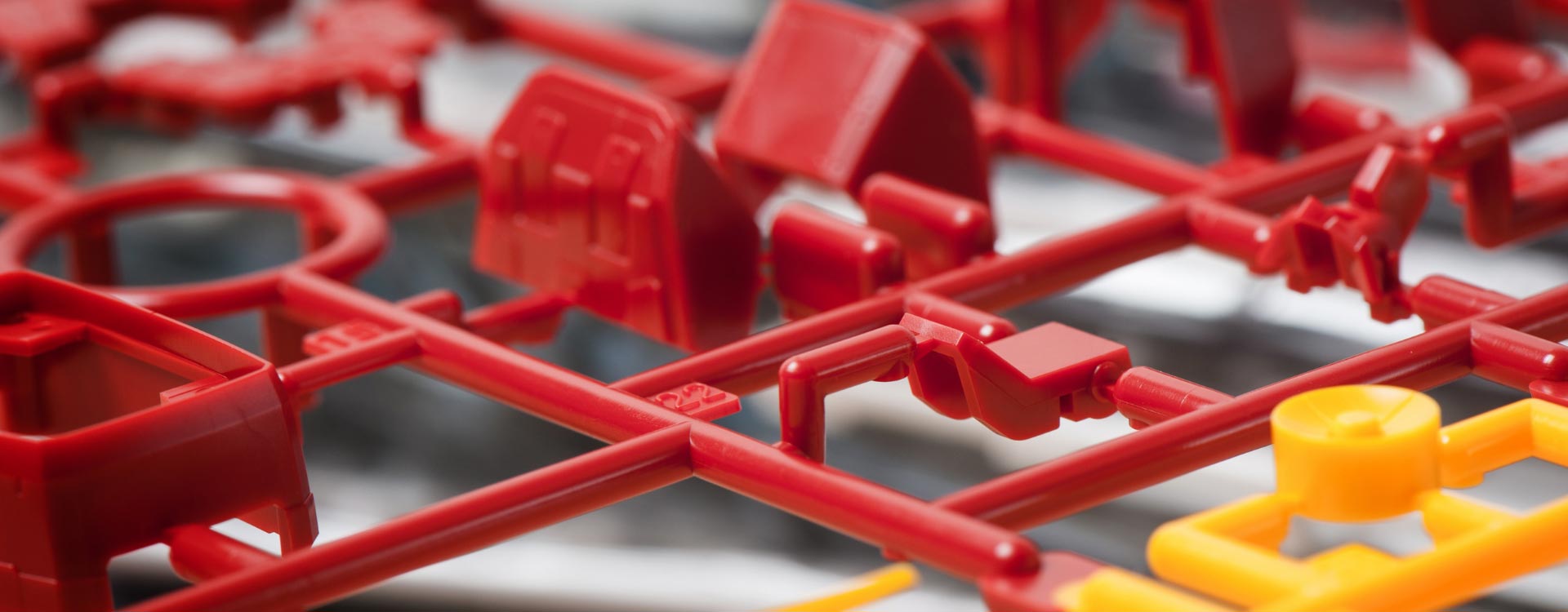

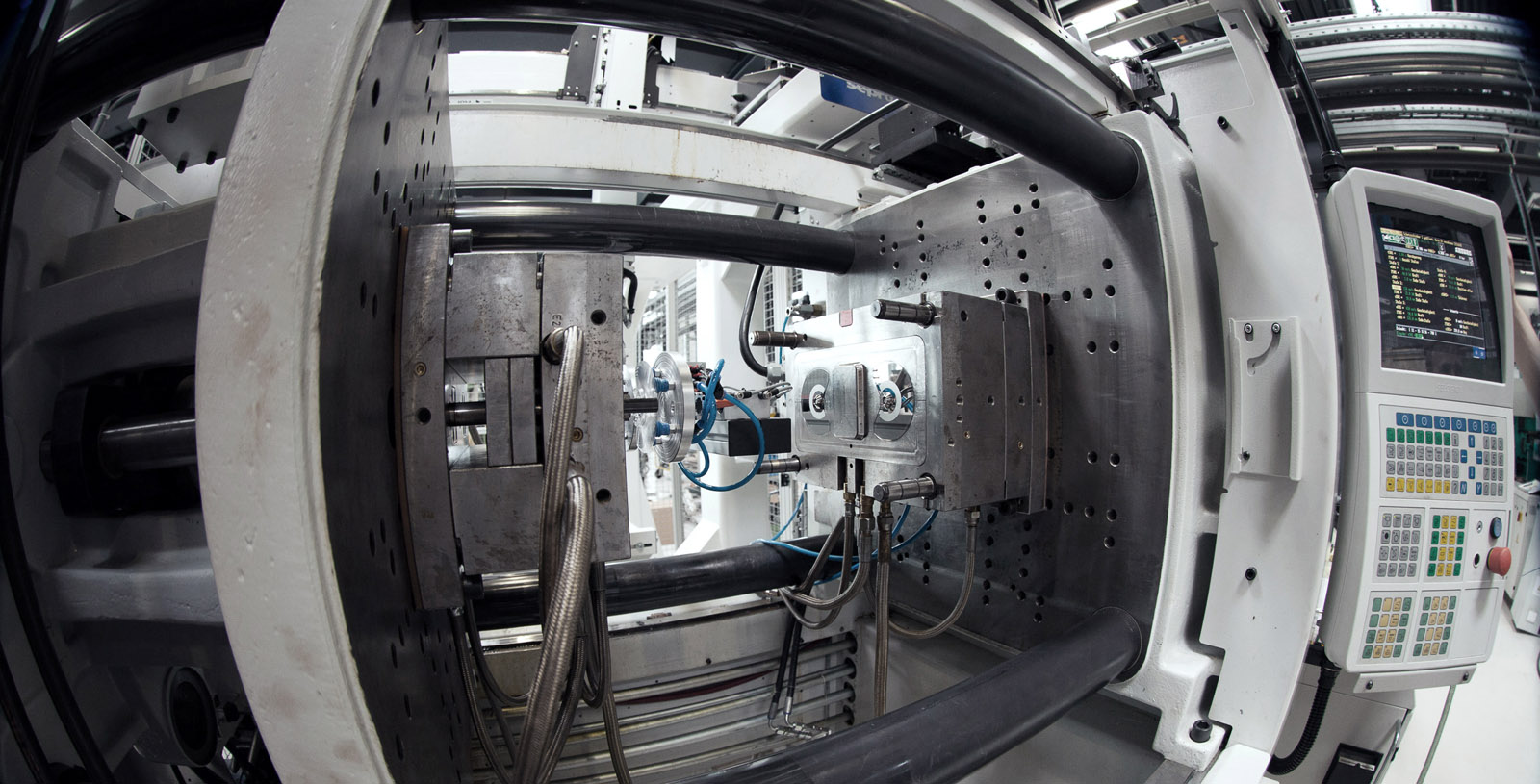

Plastic injection mold manufacturing and plastic part production are carried out with professional processes tailored to mass production needs. Both subcontracted and project-based production services are offered in this field.

All the services we provide with high engineering knowledge, technical infrastructure, and a customer-oriented approach offer reliable, fast, and sustainable solutions in your production processes.