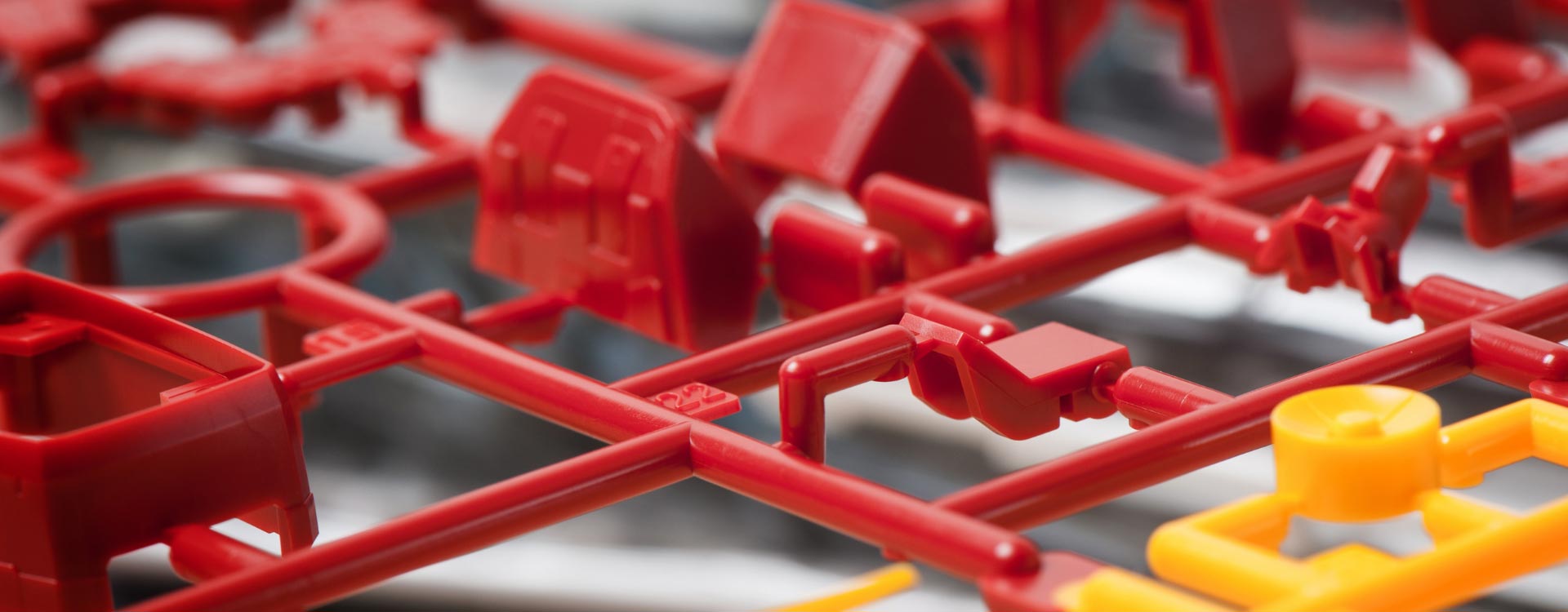

Tekmak Mold designs molds and products for many companies in the industry. In our R&D department, Mold Design, Part Design, Prototype Design, and Engineering Analyses are conducted.

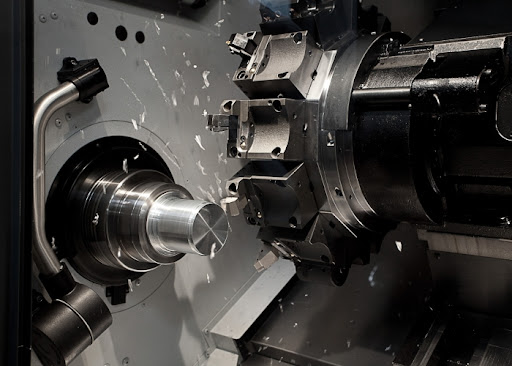

Over time, deformation, wear, and loss of function can occur in molds due to usage. Such issues negatively affect production quality and can increase downtime and costs. Mold revision, repair, and improvement processes ensure that existing molds are reused efficiently and reliably.

The revision process begins with a detailed technical analysis. Issues such as cracks in the mold, non-conforming surfaces, missing cooling channels, or ejection problems are identified. Necessary repairs are completed through processes such as reworking parts, replacing components, or surface enhancements.

Thanks to these efforts, the mold's lifespan is extended, manufacturing errors are minimized, and production continuity is maintained. This service, which offers a much more economical solution compared to new mold production, also provides significant time savings.

Our company offers revision services for both molds we produce ourselves and molds received from outside sources. With quality craftsmanship, precise machining, and technical expertise, your molds are prepared for re-use.