5 Critical Stages to Pay Attention to in Plastic Injection Mold Manufacturing

- Homepage

- Blog

- 5 Critical Stages to Pay Attention to in Plastic Injection Mold Manufacturing

Plastic injection mold manufacturing, as in many sectors, especially the automotive industry, is a process that requires high precision and experience. When this production process is carried out with proper analysis, engineering knowledge, and quality equipment, it ensures the emergence of efficient and long-lasting molds. A mold that is poorly designed or improperly manufactured can cause delays in production, increased costs, and a decline in product quality. Therefore, there are 5 basic stages to pay attention to in plastic injection mold production.

Correct Identification of Needs and Product Analysis

The first step in mold production is to accurately analyze the part to be produced according to its intended use and function. The conditions under which the part will be used, external factors such as temperature and pressure it will be exposed to, and the product's durability requirements should be evaluated. Additionally, the annual production quantity, the capacity of the production line, and the assembly location of the product should also be included in this analysis. Based on this information, the mold design created forms the foundation for subsequent stages.

Design Process and Mold Engineering

After product analysis, the mold design process begins. In this stage, modeling of the product is performed using CAD/CAM systems. The structure of the injection system, the position of the runners, cooling channels, ejector pins, and venting details are included in the design. Additionally, Mold Flow analyses are crucial for understanding the flow direction of the plastic raw material inside the mold and for ensuring proper filling balance. These analyses help identify potential manufacturing errors in advance and improve the mold's performance.

Material Selection and Machinability Criteria

The type of steel used in mold manufacturing directly affects the mold's durability and efficiency. For projects with high production quantities, heat-treated steels with high hardness are preferred; for low-volume production, more economical solutions can be used. Factors such as machinability, corrosion resistance, polishability, and strength should be considered in material selection. Standard components used inside the mold also influence quality.

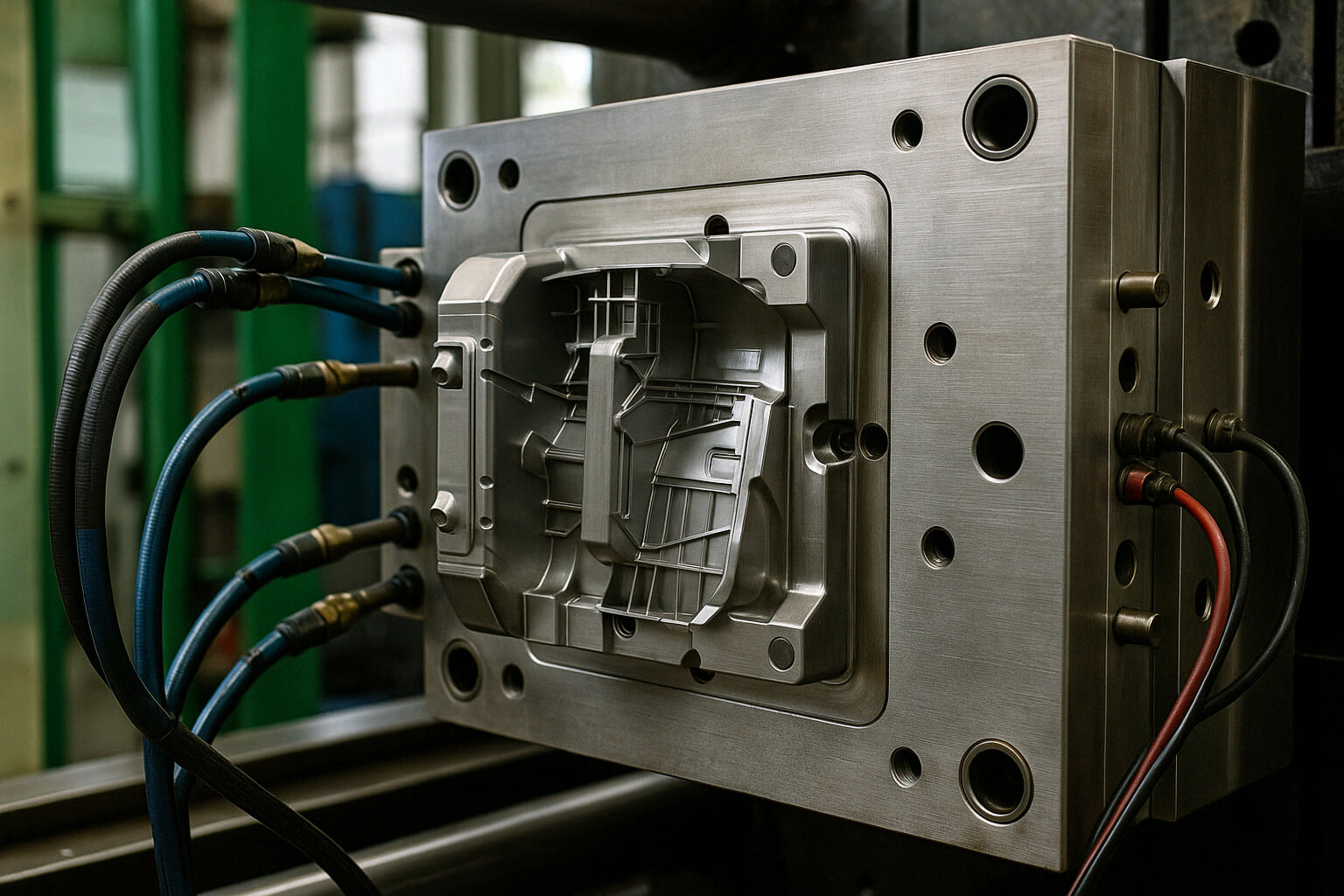

Precision Manufacturing and Assembly Process

All parts are machined with high precision using machines such as CNC, grinding, milling, and EDM (spark erosion). Surface quality and dimensional conformity directly determine the quality of the part. The produced mold parts are individually inspected before assembly, then assembled to complete the mold. Checks during assembly prevent possible dimensional deviations. This stage is a critical step that directly affects the final product quality.

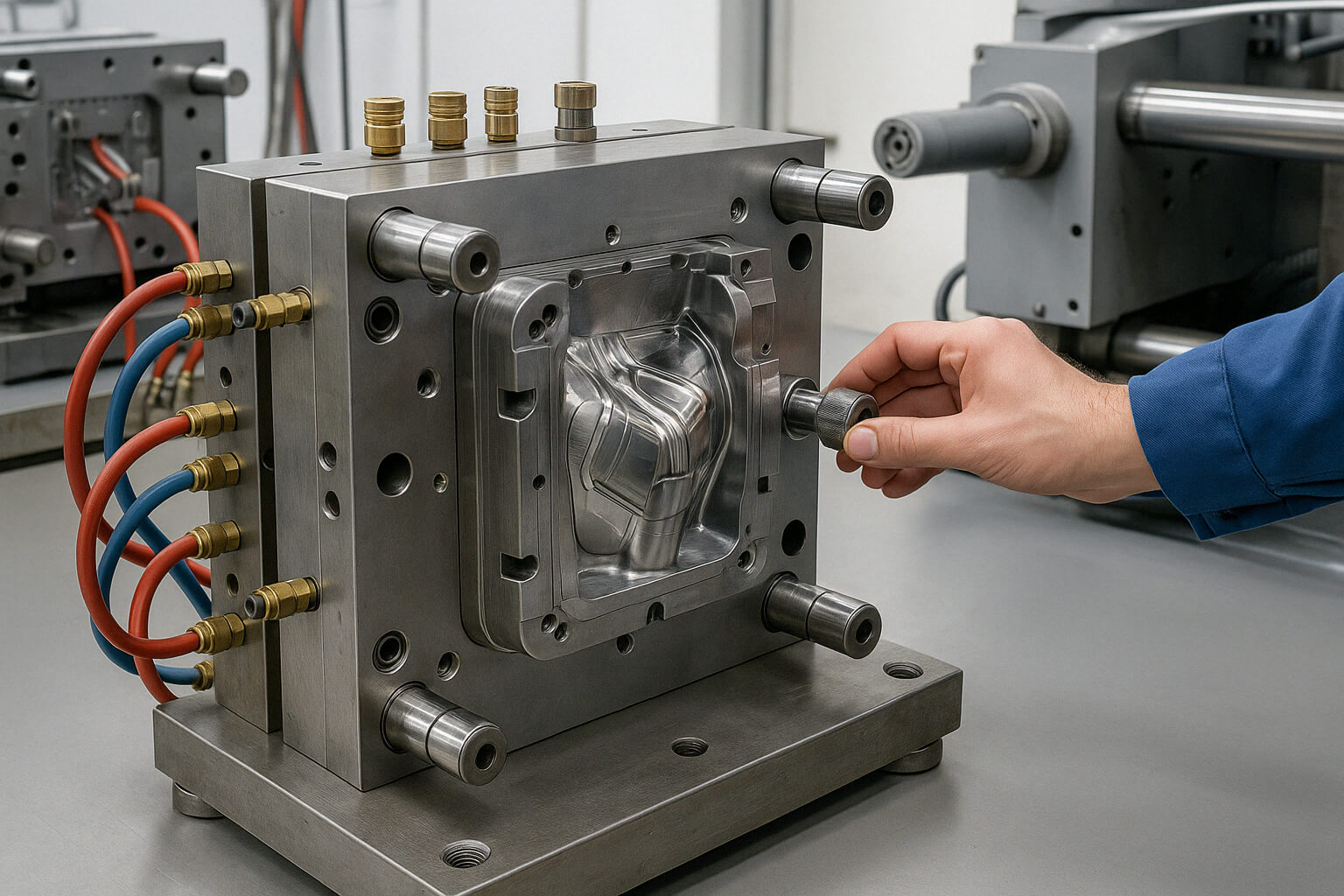

Initial Trial, Mold Revision, and Transition to Mass Production

The completed mold is connected to the injection machine for initial trial productions. During this process, errors that may occur in the part (such as flash, incomplete filling, surface defects, etc.) are observed and necessary corrections are made. After this revision process is completed, the mold is prepared for mass production. Proceeding to mass production without ensuring the mold's proper functioning can lead to serious cost and time losses.