The Role and Importance of Inspection and Assembly Fixtures in the Automotive Sector

- Homepage

- Blog

- The Role and Importance of Inspection and Assembly Fixtures in the Automotive Sector

The automotive industry is a highly competitive manufacturing field characterized by high precision and quality standards. Therefore, minimizing errors in production processes, increasing assembly efficiency, and standardizing quality control are of great importance. At this point, control and assembly fixtures come into play. These specialized manufacturing tools enhance the accuracy of quality control processes and save time in mass production.

Thanks to the application areas and contributions of control and assembly fixtures, the automotive industry can achieve more sustainable, faster, and higher quality production goals.

The Role of Control Fixtures in Quality Assurance

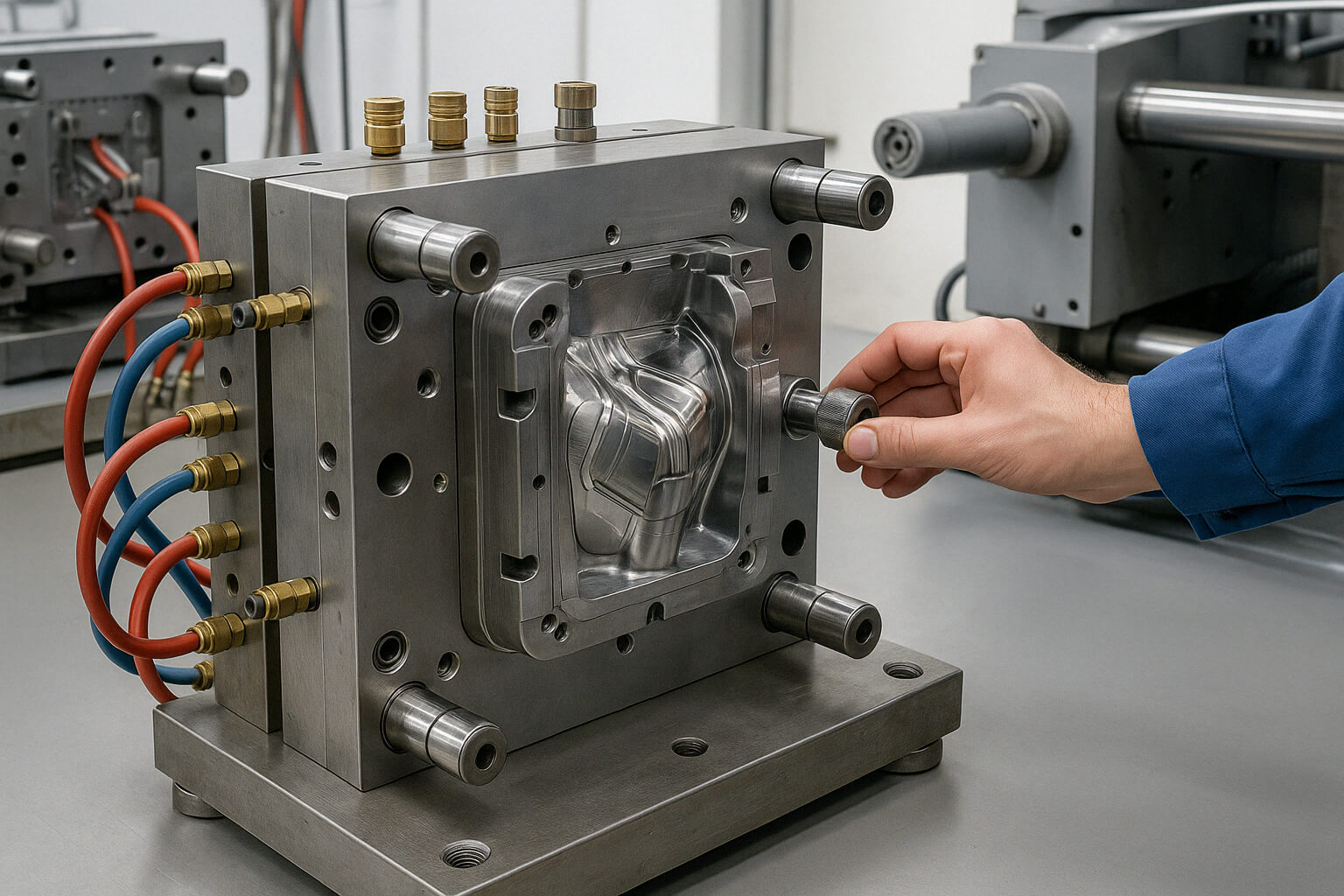

Control fixtures are devices used to verify the accuracy of measurement and tolerance values of parts produced. Especially in high-precision sectors like automotive, it is vital that parts are produced with the same dimensions and shape every time. Thanks to these fixtures, parts can be 100% inspected, deviations can be detected immediately, and necessary interventions can be made during the production process.

The accuracy of parts produced by CNC machines or plastic injection-molded products can be quickly and reliably tested with these fixtures. This not only saves time but also standardizes quality control processes.

The Contribution of Assembly Fixtures to the Production Line

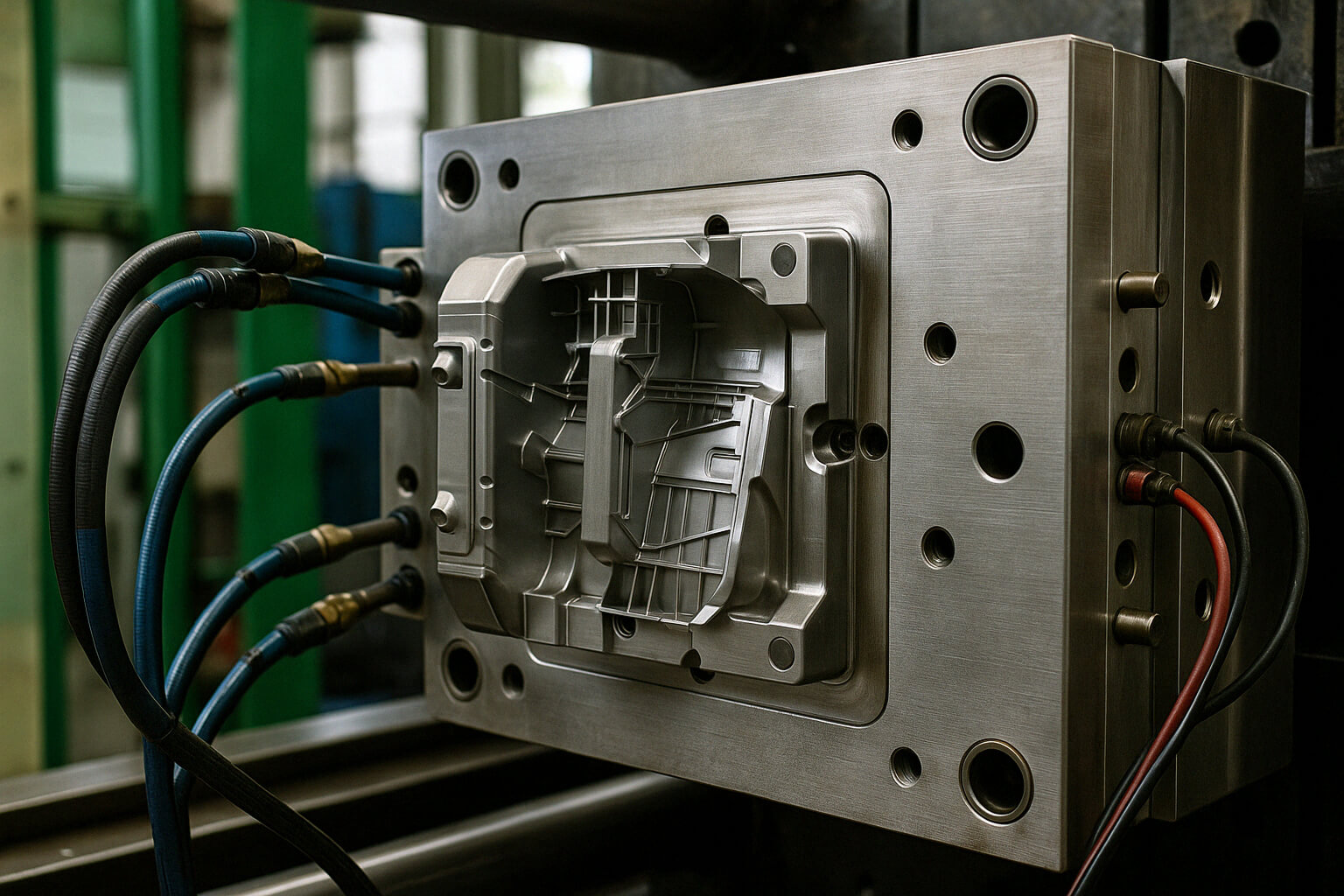

Assembly fixtures are specialized tools that ensure multiple parts are assembled in the correct order, in the correct position, and securely. In automotive production lines, assembly fixtures are actively used to minimize human error and reduce assembly time when assembling a product consisting of hundreds of parts.

These fixtures facilitate the operator's tasks, prevent problems such as incorrect assembly or misorientation of parts. Additionally, fixtures make the assembly process more ergonomic, thereby increasing workplace safety and worker comfort.

The Engineering Aspect of Fixture Design

Control and assembly fixtures are custom-designed for each project. The most suitable fixture structure is determined based on the geometry of the part to be produced, tolerance values, and manufacturing method. These designs are developed using CAD/CAM systems through 3D modeling. This engineering work, which aligns with the production flow, inspection needs, and assembly sequence, directly affects manufacturing efficiency.

The durability, machinability, and precision of the materials used in fixtures should also be carefully evaluated during the design phase. Excessive weight or low durability can cause problems during use. Therefore, both technical and ergonomic criteria should be considered together in the design.

Advantages of Fixture Usage in Automotive

The benefits provided by control and assembly fixtures in the automotive sector are quite extensive:

- Quality Continuity: Ensures that produced parts are consistent in size and shape every time.

- Time Savings: Enables quick and effective inspections instead of manual measurement and control processes.

- Work Safety and Ergonomics: Ensures operators work more safely and comfortably.

- Reduction of Error Rate: Minimizes production issues such as incorrect assembly and measurement errors.

- Increased Efficiency: The production line operates more stably without disruption to the process.

Considering that every millimeter, every second, and every detail is critical in the automotive industry, fixtures are an indispensable part of the production infrastructure.