Ways to Increase Production Efficiency with Mold Revision

- Homepage

- Blog

- Ways to Increase Production Efficiency with Mold Revision

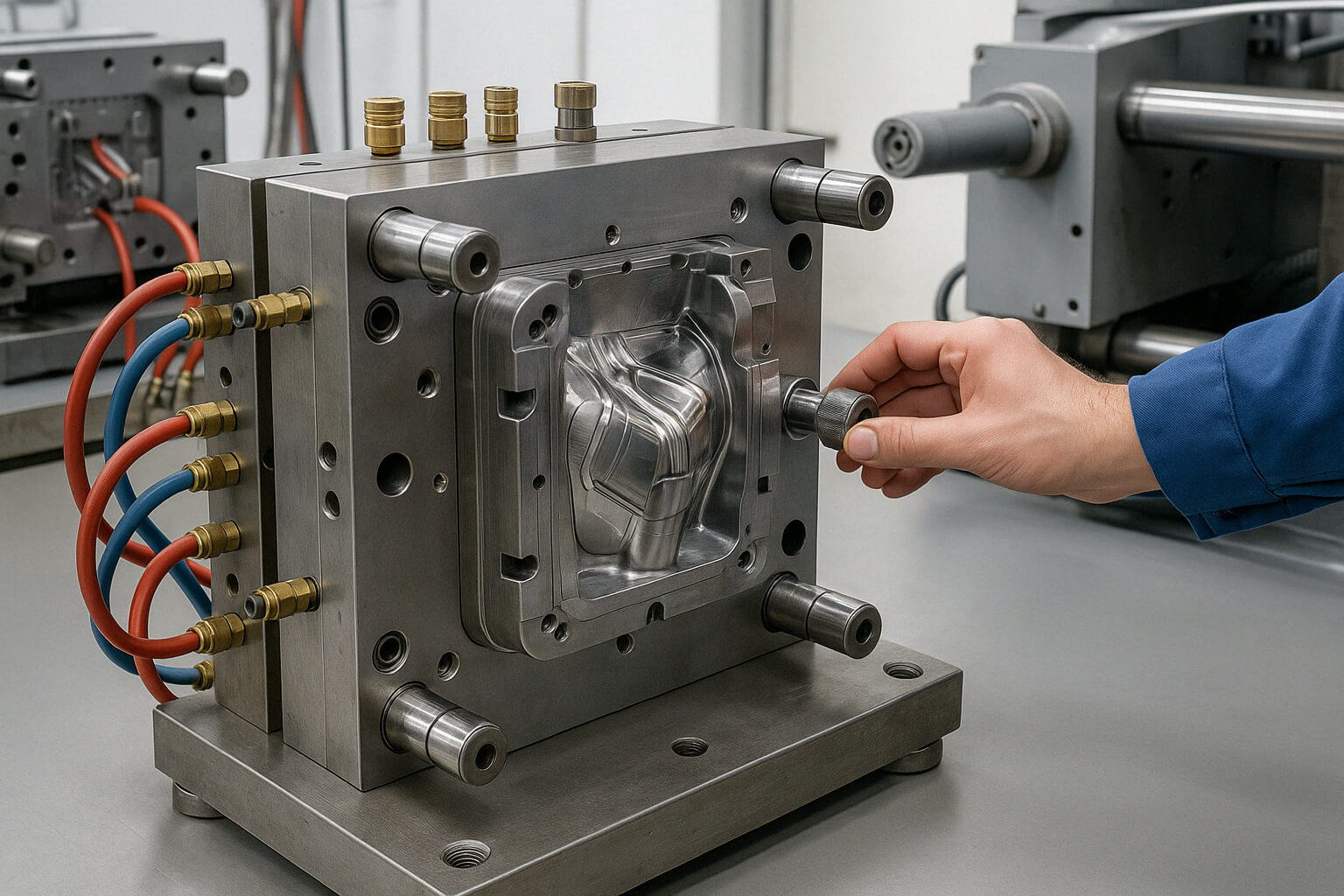

Tools are one of the most critical components of the production process. However, over time, due to intensive use, incorrect applications, or production changes, tools can deform, efficiency can decrease, and fluctuations in product quality can occur. At this point, tool revision comes into play, restoring the production process to a healthy and efficient state.

Tool revision is not just a maintenance process; it is a strategic step for the continuity of the production line and the sustainability of quality control. Properly performed revision increases production quality, reduces downtime, and significantly lowers costs.

Necessity and Benefits of Tool Revision

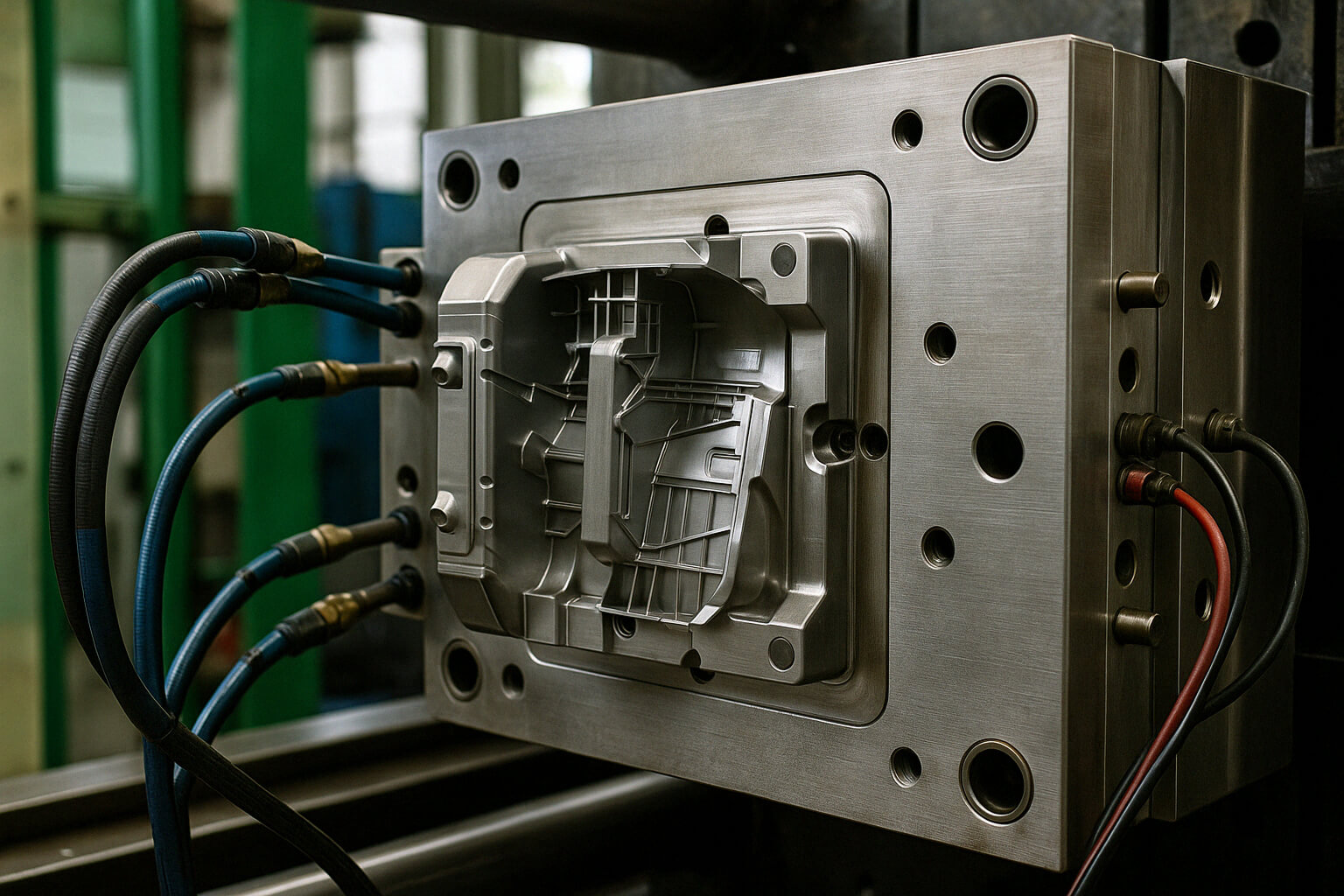

Every tool has a certain lifespan. This lifespan varies depending on the materials used, the pressure exerted on the tool, the number of injection cycles, and the maintenance schedule. Cracks, wear, or deformations that develop over time can lead to deviations in product dimensions and a decline in quality.

Thanks to tool revision, these problems are detected and corrected. Thus, balance is restored in the production process. Additionally, revision processes are much more economical than producing a new tool from scratch. While extending the tool's lifespan, costly downtimes are also prevented.

Basic Stages Applied During the Revision Process

Tool revision should be carried out systematically. The first step is a detailed technical analysis. Deformations, cracks, dimensional deviations, or surface problems on the tool are carefully examined. This analysis is performed both through physical observation and measurement devices.

Then, a revision plan is prepared based on the identified issues. This includes grinding worn surfaces, polishing, cleaning internal channels, replacing or reprocessing broken parts. Additionally, the cooling and ventilation systems of the tool are checked and improved if necessary.

In the final stage, the tool is reassembled and trial productions are conducted. Quality tests on the test parts are used to evaluate the success of the revision.

Effects on Production Efficiency

Tool revision affects production efficiency in many ways. Firstly, it ensures quality consistency. The dimensions and surface quality of products from the tool become standardized, reducing final inspection or scrap rates. This directly increases the efficiency of the production line.

Secondly, revised tools require less maintenance. This prevents unexpected production downtimes. Especially in companies doing mass production, time loss is a significant cost factor, so revision minimizes this risk.

Finally, revision makes the production cycle more stable. More efficient operation of the tool shortens cycle times and increases production speed. This directly impacts the competitiveness of businesses.

When is Revision Necessary?

Tool revision is not only necessary when the tool is damaged but should also be performed periodically. The following situations should definitely prompt a revision assessment:

- When dimensional deviations begin in parts

- When deformation or surface defects are observed in products from the tool

- When visible cracks, breaks, or wear occur in the tool

- When frequent failures occur during production

- When a loss of efficiency is felt in cooling or ejection systems

Revision processes supported by regular inspection and maintenance always keep the performance of production lines at the highest level.